Our custom capabilities extend to the full range of Spinneybeck natural materials. Working with an established network of local manufacturers, our in-house design team has experience tackling various specialized projects, ranging from tailored modifications of standard products to fully customized services. Our expertise includes color matching, specialty cutting and stitching, and complete fabrication and installation.

Colors

When it comes to creating a truly bespoke space, the opportunities are limitless. On top of our selection of over thirty leather qualities and hundreds of standard colors, many Spinneybeck leather qualities are available in custom colors. We’ll work with you to develop your own unique hue.

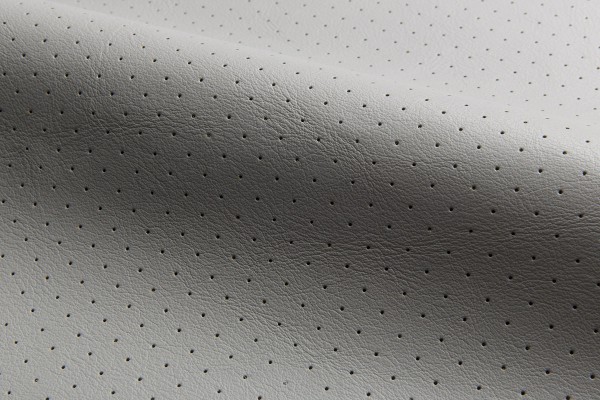

Perforation

Perforating leather introduces delicate holes in a defined pattern, enhancing upholstery and architectural products with subtle texture and visual interest. Many of Spinneybeck’s leathers can be customized with one of nine standard perforation patterns that explore geometry and repetition.

Stitching, Quilting, and Fluting

Many of our leather upholstery applications and Muro panels can be customized with stitching and quilting, adding unique detailing through patterns or a subtle infusion of color. Additionally, Muro can be further customized with fluting—a technique that involves pinching and stitching the leather to create unique and subtle linear patterns.

Engraving

Traditionally used on materials like wood and glass, Spinneybeck brings laser engraving to leather, combining the beauty and warmth of our natural, full-grain leather with the detailed precision of laser technology.

Debossing and Embossing

Debossing imprints a logo or graphic image directly into leather, creating a distinct and defined mark. In contrast, embossing raises the design to create a relief effect. Both techniques result in a striking, multi-dimensional design that adds unexpected texture to full-grain leather.

Die- and Laser-Cutting

A range of Spinneybeck products, including our belting leathers, can be die-cut or laser-cut into unique shapes and patterns for various applications, including vertical installations. The process maintains the strength of the material while adding intricate detailing for a truly one-of-a-kind design.